SUHNER Components - Successful metal parts for industrial applications

SUHNER Components include a wide range of precisely manufactured metal parts for the success of your projects. Our expertise in the production of high-quality milled parts, stamped parts and other components made of stainless steel, steel and aluminum sets new standards in quality and precision. Metal components are crucial to the performance and reliability of a machine or system. To lay the foundation for your customized solution, we dive deep into the DNA of your project. Discover the scope of SUHNER Components now!

Metal parts: The invisible heroes in the industry

The production of metal parts requires an in-depth understanding of materials, technology and customer requirements. The metal components relevant to success are the linchpin here. Our product range includes milled parts, stamped parts, bent parts and turned parts. In order to develop the perfect solution hand in hand with you, we focus on two key questions when creating components, which form the core of our collaboration:

- Needs analysis: first, we want to understand what specific needs you have for mission-critical metal components - this is the linchpin of our partnership.

- Process optimization: We then focus on how we can jointly develop and optimize your processes to not only increase your efficiency but also create future-proof solutions.

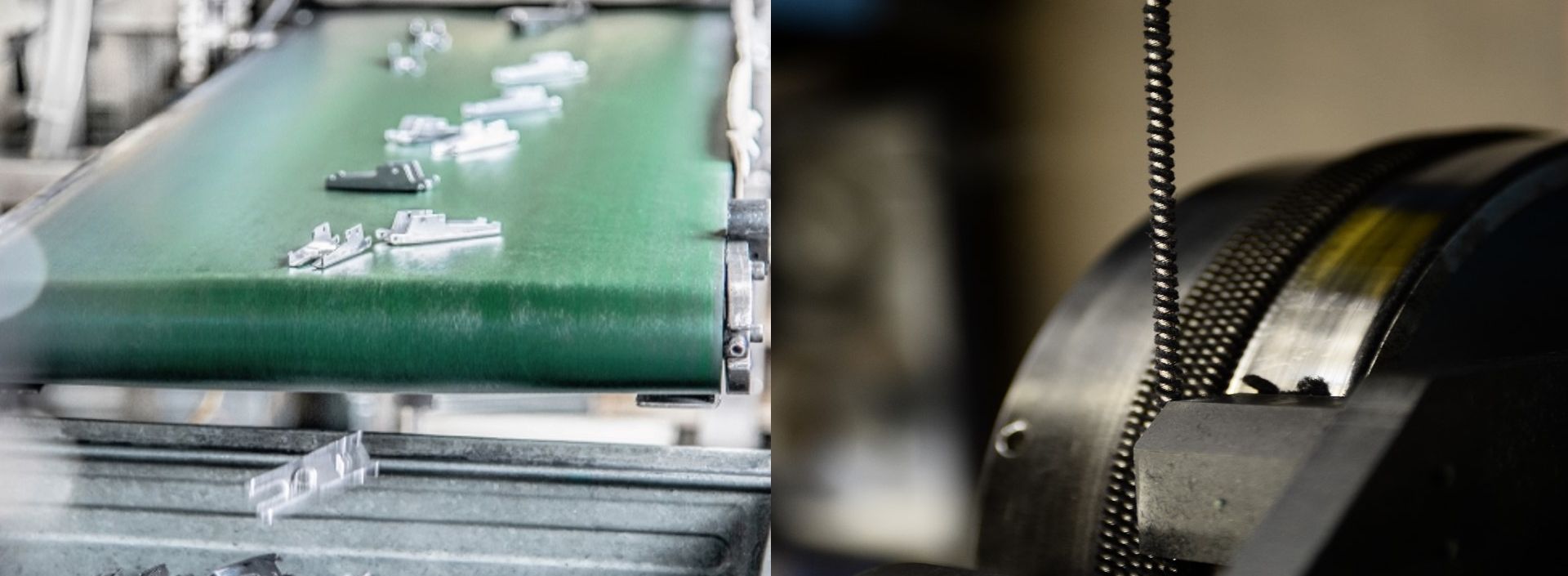

We align our collaborative work in the corresponding EcoSystem and offer you Advanced Manufacturing for the following areas:

- Stamped parts from progressive, transfer and 3D transfer technology

- Flexible drive shafts

- Spiral bevel gears

- Components for electric motors

- Prototyping

We lead the global manufacturing benchmark in these areas and are proud of our precision process

From turbines to implants: The diversity of success-critical metal components

Mission-critical metal components can be found in a variety of industries, including mechanical and apparatus engineering, power plants, aerospace and many more. They serve as essential components in complex machines and systems where precision and reliability are essential. Examples include:

- Implants and surgical instruments in medical technology, which must meet the highest standards of precision and biocompatibility.

- Transmission parts in automobiles that are permanently exposed to high loads.

- Bearings and axles in machines and systems that are critical for smooth and efficient movement.

Manufacturing these components requires specialized knowledge, advanced materials and manufacturing technologies, such as CNC technology, to achieve the required specifications and performance standards. With SUHNER at your side, you are choosing unsurpassed quality and a partner who shares your pursuit of perfection. Get in touch now!

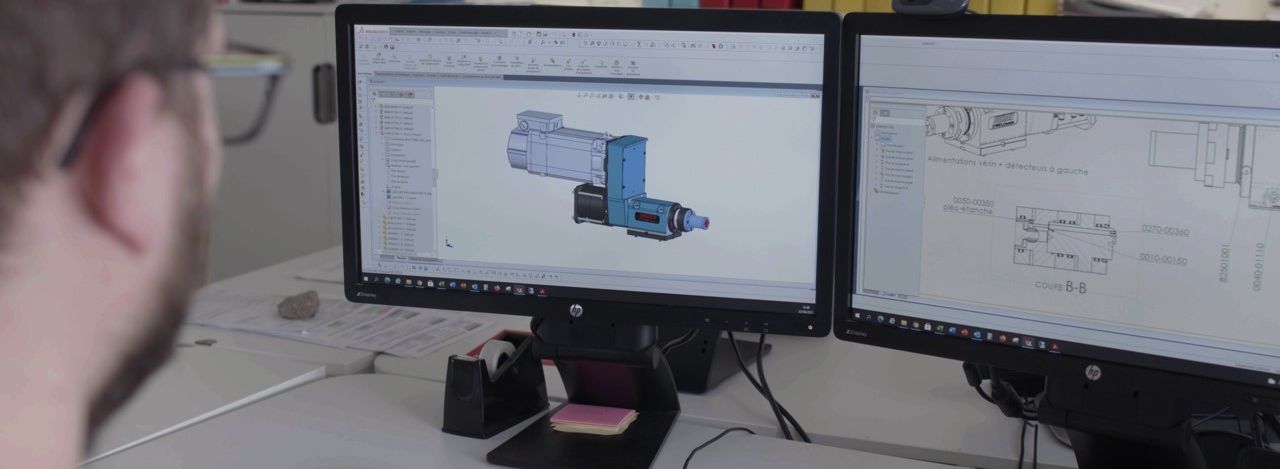

From the idea to the finished product

The production of metal parts begins long before the first cut. Our experts work closely with you to understand your specific requirements. Choosing the right material, be it stainless steel, steel, aluminum or plastic, plays a crucial role in the functionality and durability of the end products. Our manufacturing process includes:

- Material selection: We select the optimal materials based on your requirements and the application of the parts.

- Manufacturing process: Whether milling, punching, bending or turning - we use the appropriate process for maximum efficiency and quality.

- Finishing: The precision of our work is ensured by careful finishing steps such as polishing and coating.

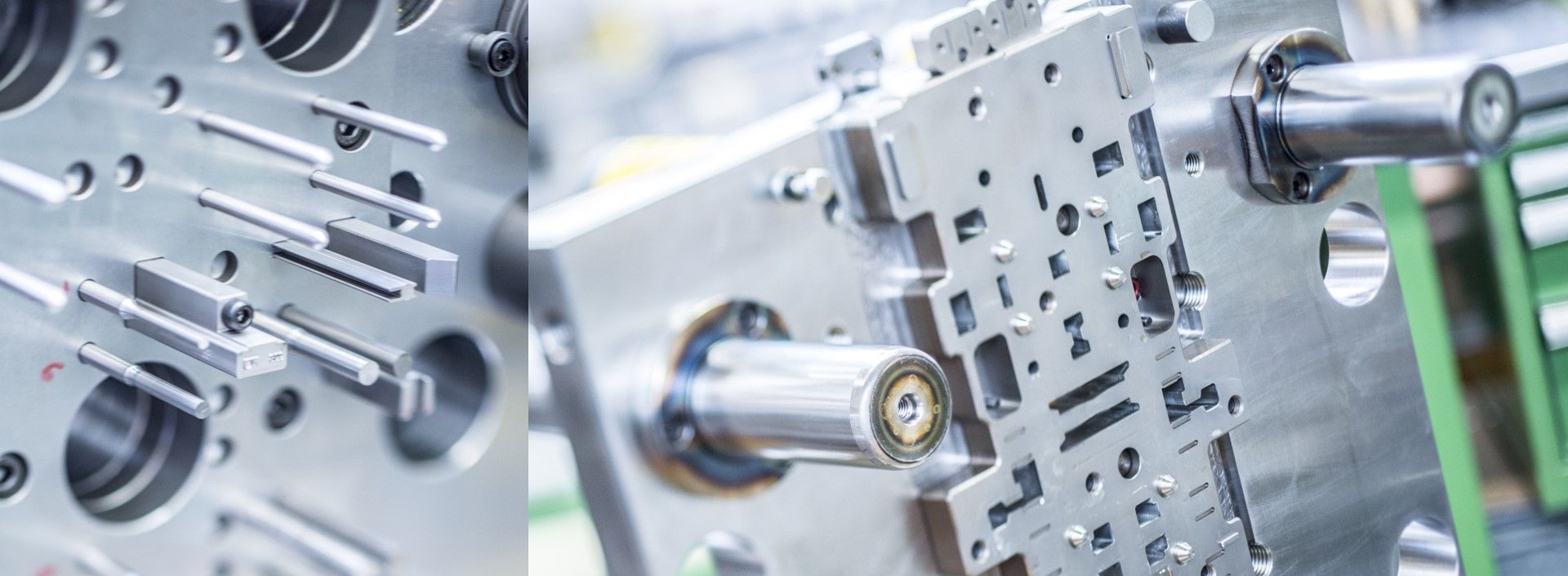

SUHNER's expertise in metalworking

The production of metal parts requires an in-depth understanding of materials, technology and specific requirements. In addition to the production of milled parts, stamped parts, bent parts and turned parts, our range also includes specialized production techniques that focus on axes, workpieces and press force. We use CNC technology with 3D metal printing to process many materials, such as

- Metal,

- stainless steel,

- steel,

- aluminum

- and plastic.

We manufacture customized products that are unsurpassed in terms of precision and quality. Our machines and milling machines are state of the art and enable us to meet even the most complex requirements. At SUHNER, we pride ourselves on being a partner to our customers. Our goal is to create unparalleled value through our in-depth understanding of materials, manufacturing and our customers' specific products. We invite you to become part of our community where quality, precision and customer satisfaction are paramount. Contact us now!

SUHNER Components - maximum efficiency for your projects

Ordering your required metal parts via our online store offers numerous advantages. A simple ordering process, various payment options and fast shipping are just some of the highlights. Our customer support team is on hand to assist you with every inquiry to ensure that you receive exactly the products you need. Choose the innovative solutions from Suhner Components:

- 3D metal printing solutions: We open up new dimensions in manufacturing with our 3D metal printing solutions.

- High quality: Our products stand for top performance and quality.

- Comprehensive know-how: Benefit from our expertise

- Dedicated customer service: Our customer support team is your rock in all project phases.

We invite you to experience the quality and precision of SUHNER Components for yourself. Choose our precision service and let our team help you select the perfect components for your projects. Start your inquiry today and benefit from our comprehensive expertise in metal processing. Together we can achieve great things - with precision that moves!

Follow us on